Aug 27th 2012, Fitz and Warnick buy a pair of Mutts off of Craigs List from a seller in Drexel, Missouri. Both are crushed, one of them is a later model American General M151A2 that is destined to become Mutt 6022.

Work grinds to a start on 6022. This one came to us with a damaged front wheel bearing so we had to change the drivers front hub assembly just to be able to roll it. Prior to that, we had to move it around like a wheel barrow just picking up the front end and rolling on the rear tires.

Yanking out cut off sections of the ROPS roll cage.

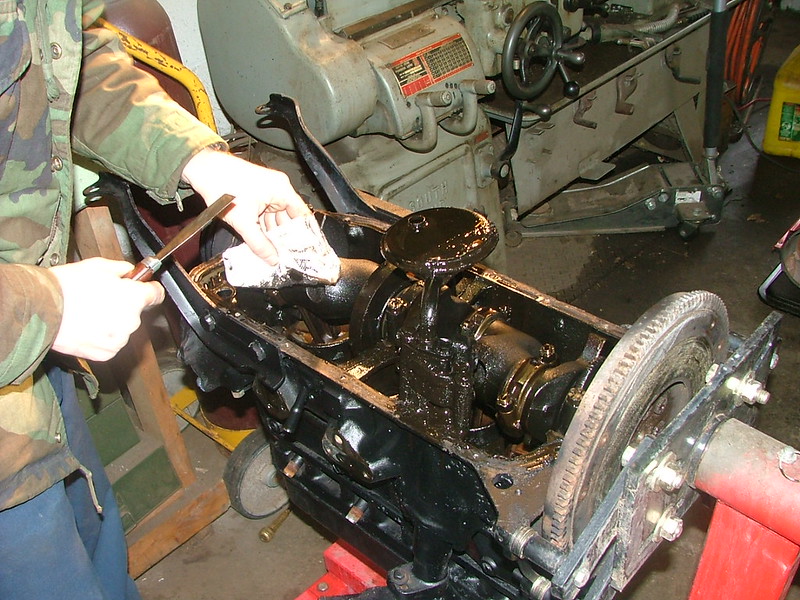

Original transmission, not so good!

Getting the front end together.

Flipped on it's side for clean up. Was nice to see that the underside was in good shape and that the main support up front had been repaired quite well therefore saving us the usual hassles of doing it.

As part of the demil process, 6022 had it's suspension cut by the gov prior to being passed out of service. Here Dave it carefully stitching it back together.

Davey and Curfman, taking loose the shocks and removing the springs to let the suspension flip all the way back for easy access to do reweld work.

Poor 6022 was always stuck playing second fiddle. Here it is after having it's front end and power pack stolen to stick in 6007 since it was judged at the time that we'd get 6007 on the road sooner. In the picture, Fitz is installing the front end from 6007 which, in an odd twist, has a bad bearing just like the original front end that was in 6022 all those months ago...

6022 as it sat in April 2013.

_______________________________________________________________________________________________________________________________________________

December of 2013 we decided to switch the front ends back around between 6022 and 6007. Here David is retrieving 6022s front suspension off of 6007.

Front suspension up on saw horses in the (heated) shop for refurb.

Getting the axles pulled out.

Hub cleaned out with new races pressed in.

Front brakes all done.

Flipped over, top side cleaned up and painted. Tidied up a few loose ends while we were here as well.

Quality control staff approve.

_____________________________________________________________________________________________________________________________________