I pulled the plugs and they had all been doing their thing in a lean mixture condition. No surprise there.

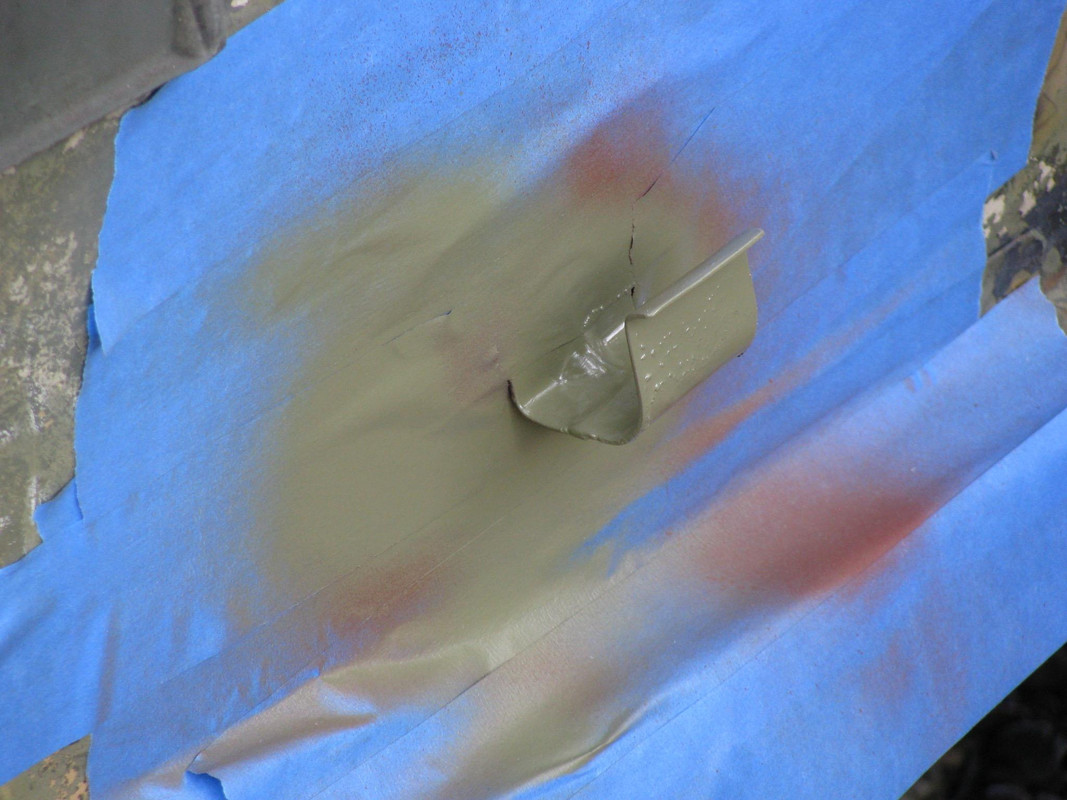

So, it was time to pull the carb and replace it with one of Brooks' special rebuilds. However, my rebuilt carb was from an earlier truck so a modification had to be made and this mod was personally approved by Mr. Brooks.

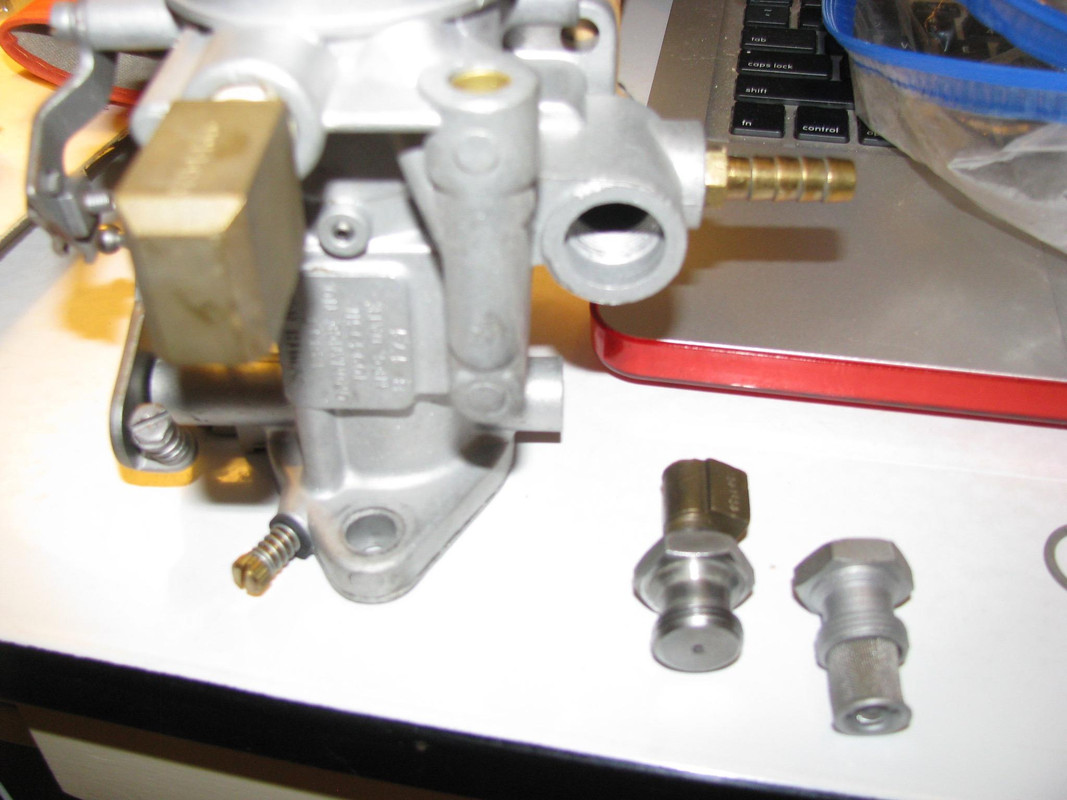

What you see here is a Zenith carburetor that predates the carb on my A2. The fixture on the right is what belongs on this carburetor (note the wire screen.) The fixture on the left, came from my original carb. The fixture on the right is blind. It has no fitting on top. Were I to put the fixture on the left on this carburetor gas would be unable to flow to the carb. This fixture can be modified to work on the rebuilt carb but, once modified, it cannot be used with the original carb. In this modification, Mr. Brooks' solution is to make three angled cuts across the threads. The total volume of these cuts approximates the normal volume of fuel that the carb needs to function properly.

Pardon the focus...but you get the idea...

It is critical that the threads are clean and completely free of debris after the cuts are made. This can be accomplished by detailing the threads at the cuts with a fine file.

After installation, the truck fired right up and the engine ran correctly. Mr. Brooks' settings were absolutely spot on with no flat spots as promised but there must be balance in the universe so.... after a short drive around the back lot the truck wouldn't start again.

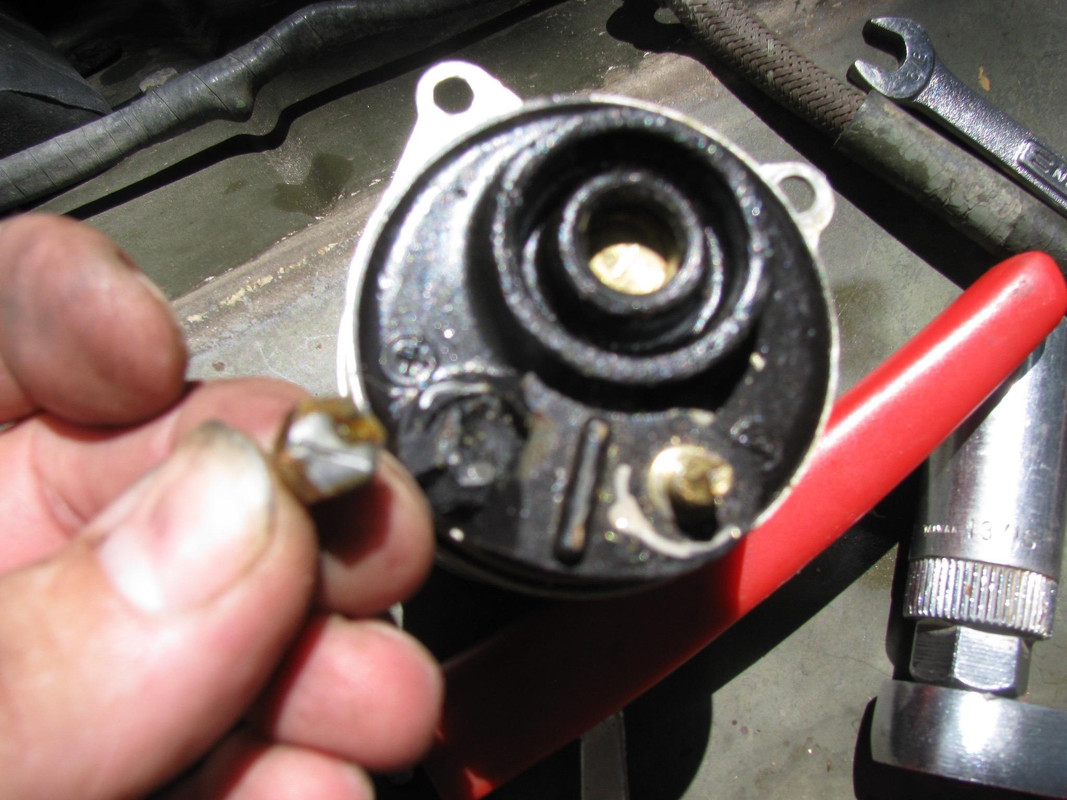

Pulled a plug wire and got no spark. So I went into the distributor and found...

THIS.

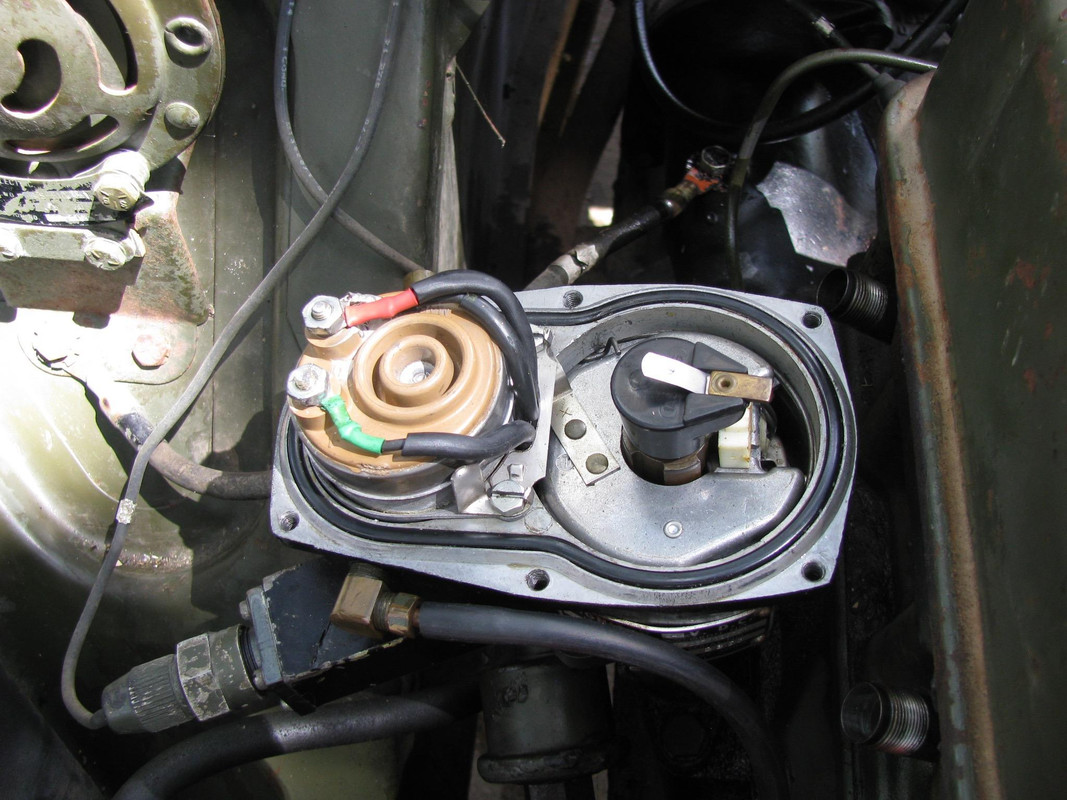

The resin around the brass lug was broken away and missing altogether (which means someone had been in there before me) and the lug is (was) soldered to a small wire. Had someone taken the time to reset that lug with some resin it probably would have been ok but the wire was no longer attached to the lug and the problem was intermittent depending wholly upon what kind of bumps the truck had endured while being driven. It's the little things that get ya. So I got into my great big box of everything and found another 24V coil (unproven) and installed it.

And, we are back in business!!! Runs, drives, stops, has brakes, lights and a horn. Wow.

Next up....maintenance. Lots and lots of maintenance.